Grain Dryer

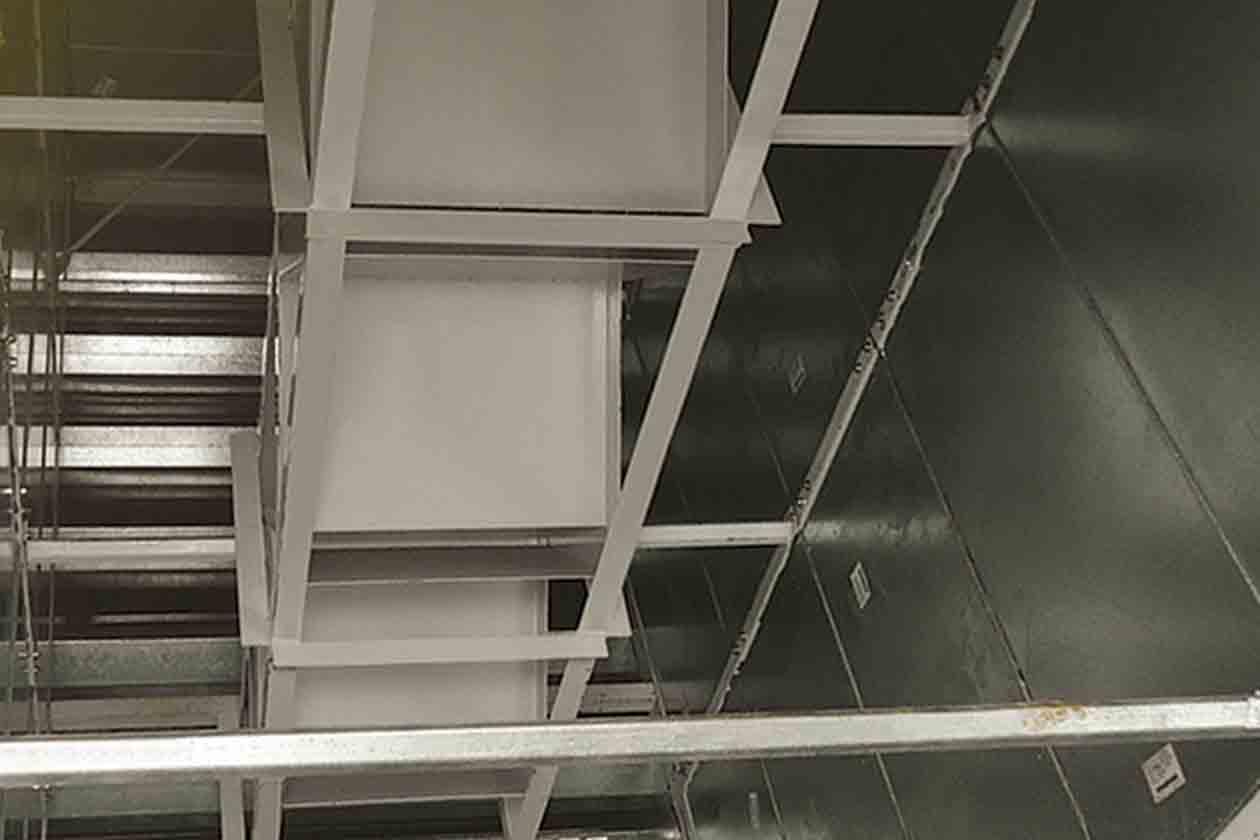

The AGI Grain Dryer has been developed to promote efficient grain drying. With a robust structure, composed of a silo box, exhausts, drying tower and sluice box, it is designed to optimize the drying process and preserve grain quality. It is finished with galvanized sheets that, in addition to providing longevity, also mean it can be installed in different environments and under different climactic conditions. Assembly is simple and modular.

Double Circulation Dryer (patent)

The Double Circulation Dryer enables more homogeneous and efficient grain drying. As the grains are transported to the drying tower, they are exposed to hot air from at least four points in each duct, which are in the form of overlaid trestles. This system ensures that the drying air has less drag as it passes through the grain.

Double Circulation Dryer (patent)

The difference with this model is that it protects the grains throughout the drying process, from the time it enters the silo, to when it passes through the drying tower. The buffering ladder enables the grain to be distributed equally throughout the tower, helping to preserve it. As the grain passes through the drying tower, it is exposed to hot air released from at least four points in each duct, which are are in the formal of overlaid trestles. This system ensures that the drying air has less drag as it passes through the grain.

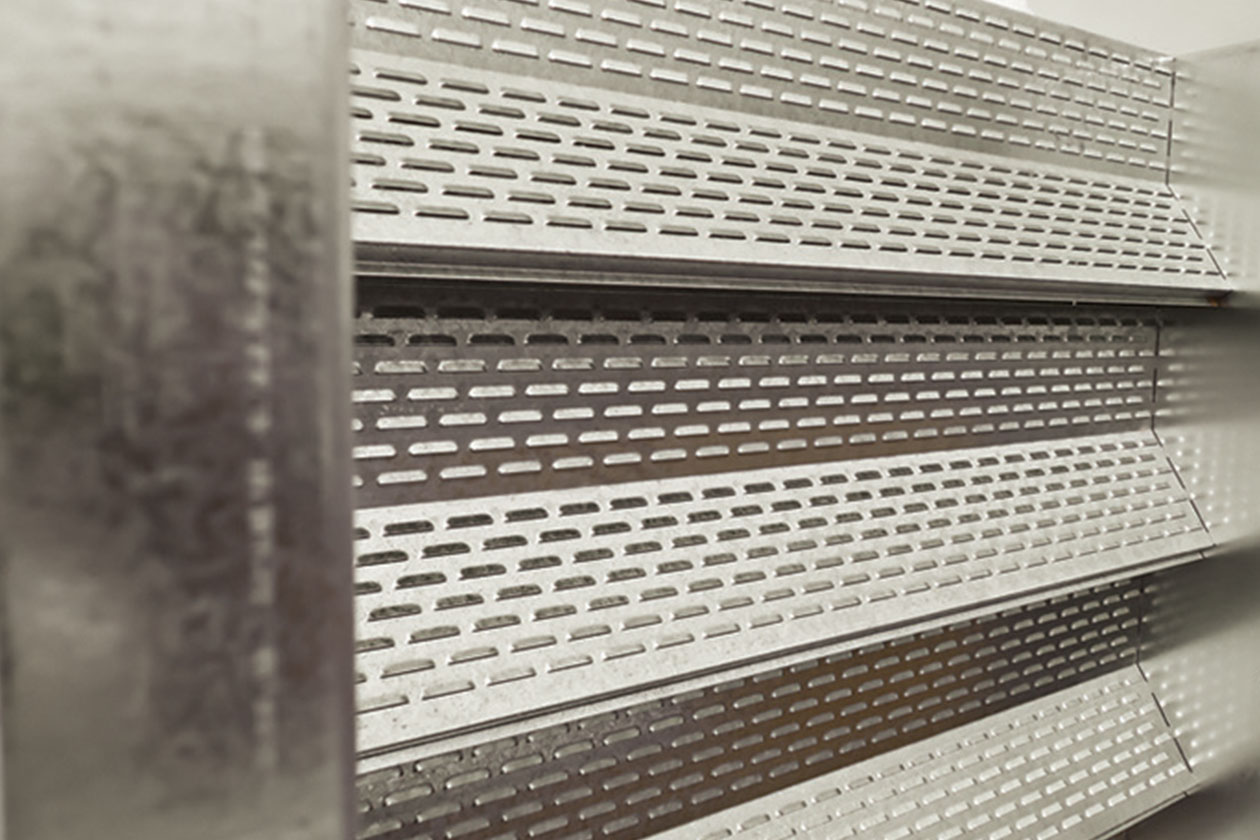

Perforated column system (patent)

With this sytem, the drying takes place as the grain comes into contact with hot air, as it moves through the drying tower. The perforated duct columns enable not only greater thermic exchange, but also better circulation and air contact with the grain, which contributes to more effective drying of the product.

Contact Informaton

AGI Brasil Head Office

Alameda Santos, 2441, cj 62, São Paulo/SP/Brasil

Sao Paulo, Sao Paulo, Brazil

01419-101

Phone: +55 11 3894-3000

Fax: +55 11 3894-3000

Email: vendas@aggrowth.com